|

Technology

> Technological Process

|

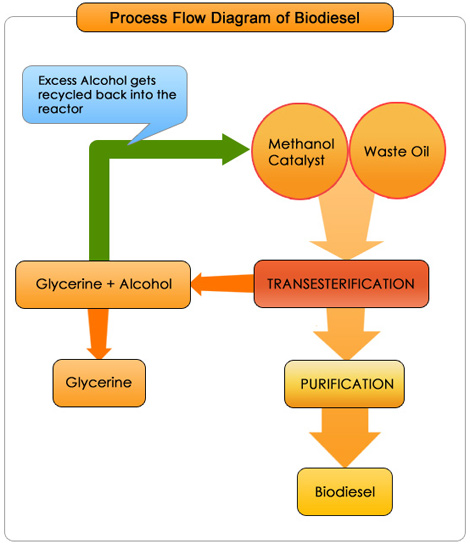

Technological ProcessBiodiesel is a transparent liquid below room temperature and its colour is yellow or colourless depending on the nature of the feedstock. Pure biodiesel (B100) can be used directly or blended with fossil diesel at any given ratio. For example, B5 is a blend consisting of 5% biodiesel and 95% by volume of fossil diesel. All these (B5, B20…B100) are compatible with diesel-run vehicles because biodiesel has similar physical and chemical properties with fossil diesel. The manufacturing process of biodiesel involves the transformation of renewable raw materials such as vegetable oil and animal fat into mono-alkyl esters of long chain fatty acids. Under specific conditions, the oils (main component: triglyceride) can react with methanol to produce Glycerol and biodiesel (Methyl Esters). Our production line is designed to allow multi-feedstock with maximum capacity of 100,000 tons biodiesel production per year. We are able to handle various kinds of feedstock from the worst to the best. All the processes are fully automated. The most important is that we are located in Hong Kong Ecopark which An Environmental Impact Assessment (EIA) was carried out in respect of air and water quality, waste management, land contamination, landfill gas hazard and hazard to life to ensure all of our production processes are clean and have no significant environmental impacts to the surrounding areas.

|

|